- ai field service management

- Commercial Equipment

- fsm

- FSM for commercial equipment companies

Commercial Equipment Business Software: A Way to Reduce Cost

Key Takeaways:

Here’s a quick overview of how the right software can save money and enhance the operations of commercial equipment service:

- Business software in commercial equipment helps prevent expensive failures by organizing maintenance and scheduling.

- Automated equipment maintenance scheduling and planning enhance the productivity of technicians and the reliability of services.

- Online work orders and mobile access save time in administration and reduce billing mistakes.

- Scalable, low-cost solutions are beneficial for small businesses, as they enhance efficiency without incurring unnecessary overhead.

- Field service teams have access to platforms like Praxedo, which provide real-time visibility, smart dispatching, and cost-saving capabilities.

Companies that handle the installation, maintenance, or repair of equipment in more than one location often experience increased service demands, heightened competition, and reduced profit margins.

That is where commercial equipment business software can be used. These platforms enable teams to manage technician schedules more effectively, automate service workflows, minimize downtime, and enhance cost visibility.

What Is Commercial Equipment Business Software?

Commercial equipment business software is a type of digital tool used to help companies manage their service operations more effectively, including dispatching technicians, tracking assets, and performing preventive maintenance. This software is specifically designed to support businesses that maintain, repair, or inspect commercial and industrial equipment, unlike generic scheduling platforms.

Understanding the Hidden Costs of Equipment Downtime

Unplanned Repairs Disrupt Workflow and Budgets

Maintenance that is not planned or scheduled is reactive in nature, and reactive repairs are nearly always more costly. Emergency visits usually involve overtime work, ordering parts at the last minute, and rescheduling other jobs. When a technician is already in the field, making urgent calls results in inefficiencies and hurried service.

In industries such as commercial kitchen equipment, copier maintenance, or EV charging stations, a failure may lead to business disruption for your client. That puts extra strain on your team and may result in lost contracts or SLA fines. These scenarios are more challenging to foresee and manage without reliable equipment maintenance management software.

Poor Preventive Maintenance Reduces Equipment Lifespan

Failing to maintain a systematic equipment maintenance program not only exposes the equipment to short-term breakdowns but also accelerates wear and tear. Over time, components wear out more quickly, and minor issues can escalate into costly repairs. The result? Increased capital spending and asset turnover.

This is where planned equipment maintenance is essential. Even robust industrial equipment will not last long without regular checks and simple maintenance. Manual systems or simple spreadsheets used by businesses often overlook important service dates, leading to unnecessary repairs and downtime.

Manual Workflows Increase Admin Time and Errors

Most companies continue to use paper forms or disconnected systems to track jobs, technician updates, and equipment status. These manual processes introduce hidden expenses, including time wasted in searching for information, correcting errors, or resolving billing disputes.

For example, if a technician fails to document a part used or forgets to sign, the office staff may not be able to close the work order or charge the client correctly. These minor inefficiencies multiply quickly in high-volume settings. Without equipment maintenance software for small businesses or enterprise-scale operations, maintaining accuracy becomes a daily battle.

The Role of Maintenance Scheduling in Reducing Costs

Planned maintenance is the foundation of cost-effective equipment management. In its absence, companies are left to do catch-up repairs, resulting in unplanned downtime and costly service calls.

With the assistance of software, companies can transform the way they manage assets and reduce operational costs by adopting a structured scheduling approach.

What Is an Equipment Maintenance Schedule?

An equipment maintenance schedule is a systematic plan that outlines the scheduled service intervals for each piece of equipment. It includes preventive activities such as inspections, cleaning, part replacement, and time-based, usage-based, or manufacturer-based calibrations.

For businesses that manage various types of assets, including HVAC systems, electrical appliances, or production equipment, understanding what constitutes an effective equipment maintenance schedule is the first step towards long-term cost control. These schedules are typically inconsistent and prone to human error when handled manually. However, with a dedicated system such as industrial equipment maintenance software, schedules can be automated, monitored, and modified in real-time.

Benefits of Scheduled Equipment Maintenance

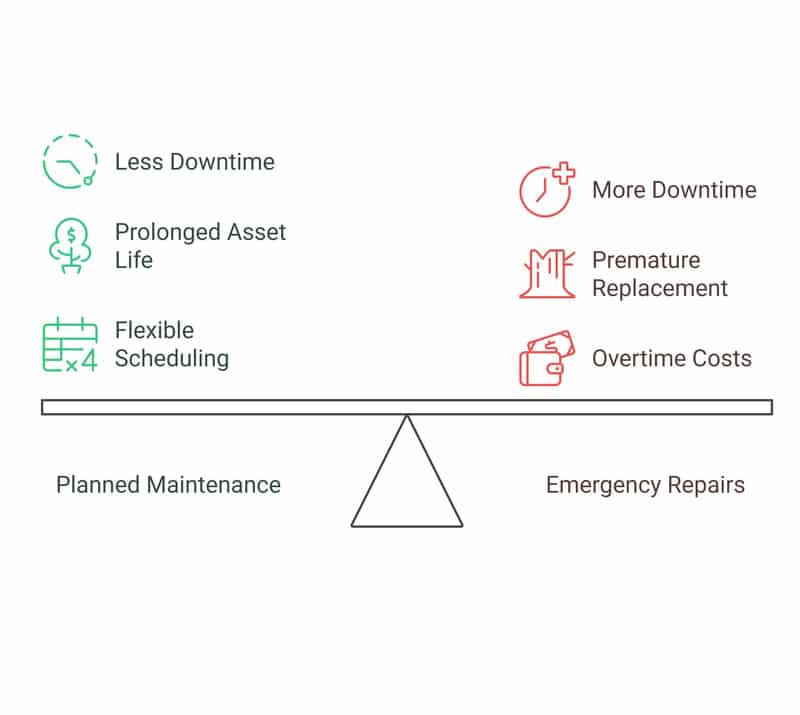

The short-term advantage of planned equipment maintenance is less downtime. Routine maintenance is used to identify issues before they become serious, reducing the number of emergency repairs. It also prolongs the life of your assets, allowing you to save on the cost of premature replacement, which can be a significant expense.

Additionally, you can schedule your service to accommodate the availability of technicians, parts ordering, and client needs. This saves on overtime, enhances customer satisfaction, and increases efficiency. Equipment maintenance management software allows you to automatically allocate jobs, recurring tasks, and compliance all in one dashboard.

How Equipment Maintenance Software Drives Cost Efficiency

Automates Planning Through Smart Scheduling Tools

Manual scheduling can be effective when you have a limited number of assets, but it is inefficient as your business expands. Smart equipment maintenance scheduling tools can be used to automate repetitive tasks, allocate technicians according to their skills and availability, and make sure that no task falls through the cracks.

Solutions like Praxedo utilize dynamic scheduling to optimize routes and service priorities, thereby minimizing idle time, fuel expenses, and administrative effort. With a well-planned day, every technician can accomplish more with less waste, and your team will stay focused on billable work.

Real-Time Field Operations and Technician Management

Real-time visibility is crucial in industries where timely responses are essential. Using commercial business software, dispatchers can assign jobs in real-time, track the status of technicians, and dynamically modify schedules.

Such live coordination results in the improved utilization of labour resources and accelerated service delivery. In teams that handle urgent work or those with multi-site service contracts, it is essential to know the location of technicians and what they have already accomplished.

Digital Work Orders Eliminate Redundant Admin

One of the least considered cost drains in any service business is paperwork. Lost forms, manual data entry, and billing errors may slow down invoicing and damage your cash flow. This is why an increasing number of companies are implementing equipment maintenance software for both small businesses and enterprise teams.

Digital work orders enable technicians to record work, collect client signatures, capture photos, and complete checklists directly on their mobile devices, streamlining the workflow. All this information is stored in the cloud and shared in real-time with the back office.

Calculate the Cost of Downtime vs. Software Investment

Downtime Is More Expensive Than Most Realize

Unplanned equipment failures cause schedule disruptions, the postponement of other service calls, and, in most cases, necessitate the use of premium parts or overtime work.

For businesses that provide services to critical commercial infrastructure, such as electrical appliances, HVAC systems, or industrial equipment, the cost of a lost job can be thousands of dollars. According to an Aberdeen Group report, “The average cost of unplanned downtime across industries is $260,000 per hour.”

Wasted time, fines, and broken customer confidence are all detrimental to your bottom line. And when you multiply that by a busy week or month, the figures are noteworthy. Without a structured equipment maintenance schedule in place, these costs are not visible until it is too late.

How Software Quickly Pays for Itself

The good news? Software is not a tool, but an investment. An effective commercial equipment business software platform eliminates errors, streamlines billing cycles, and keeps field teams focused on revenue-generating activities.

A cloud-based equipment maintenance software solution can offer significant efficiency benefits, even for lean teams, without requiring substantial changes to the infrastructure.

How to Mitigate Risk During Equipment Maintenance Software Implementation?

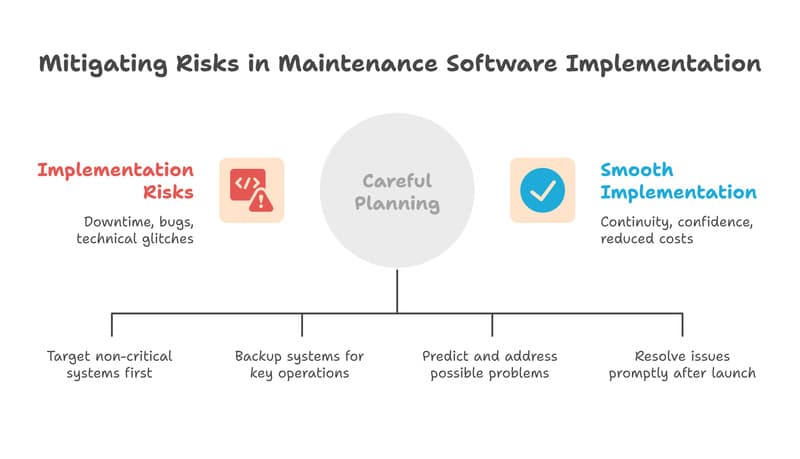

Although the advantages of maintenance software are obvious, businesses should also be prepared to address the common risks associated with the implementation process and prevent them through careful planning.

- Risk: System Downtime During Implementation: Due to the integration of new systems, the first consequence is the potential downtime or performance issues that may interrupt operations and result in a loss of revenue. Unexpected closures may also hurt corporate confidence and spirit.

- Mitigation: Phased Rollout with Redundancies: Roll out the new software in stages, targeting non-critical systems to minimize impact. Create redundancies and backup systems to ensure the continuity of key operations in the event of unforeseen downtime.

- Risk: Software Bugs and Technical Glitches: The deployment of new software is frequently prone to unexpected bugs and glitches that can impair performance and diminish confidence in the system. Such problems may lead to delays and increased operational costs.

- Mitigation: Intensive Testing and Timely Technical Support: Perform a comprehensive testing of different situations to predict and address possible problems before full implementation. Have a responsive technical support team to resolve any issues that may arise promptly after the launch.

Conclusion

The road to greater margins does not necessarily involve raising prices; sometimes it is a matter of working smarter. With the right equipment maintenance management software, commercial service providers can minimize overhead, prevent unexpected repairs, and make the best use of time and labour.

Whether it is planned equipment maintenance or digital work orders and dispatching technicians, platforms such as Praxedo provide the tools to modernize your operation. Software designed to fit your industry can deliver real savings and a definite competitive advantage, whether you are managing a large industrial field team or a small crew.

If you are still using manual systems, it is time to consider how industrial equipment maintenance software can streamline your business and improve your profits. To learn more, get in touch with us.

FAQs:

1. What is commercial equipment business software used for?

It is created to assist service companies in scheduling, maintaining, and tracking commercial equipment. It simplifies the dispatching of technicians, tracking of jobs, and planning of preventive services.

2. How does scheduled maintenance reduce equipment costs?

Regular maintenance prevents costly emergency repairs and prolongs the life of equipment by having businesses perform routine maintenance. It also enhances planning and allocation of resources.

3. Is equipment maintenance software suitable for small businesses?

Yes, numerous platforms, such as cloud-based ones, are designed to support small teams. They facilitate the effective management of service operations without requiring complex IT infrastructure.

4. How quickly can software like this pay for itself?

The cost of the software is often recouped within months through savings in downtime, quicker billing, and reduced administrative time. It provides quantifiable ROI in terms of operational efficiency.

Our similar articles.

-

- energy and utilities

- utilities

- fsm

- AI in field service management

Scheduling Software for Utilities Companies: How to Optimize Workflows and Resources

September 15, 2025 -

- pest control

- fsm

- field service technician

- AI in field service management

How Pest Control Business Software Can Streamline Operations

December 9, 2025 -

- fsm

- AI in field service management

- Pool service technicians

Maximize Productivity With Pool Service Software

August 29, 2025