- Field Service Management

- Industries

- Optimization

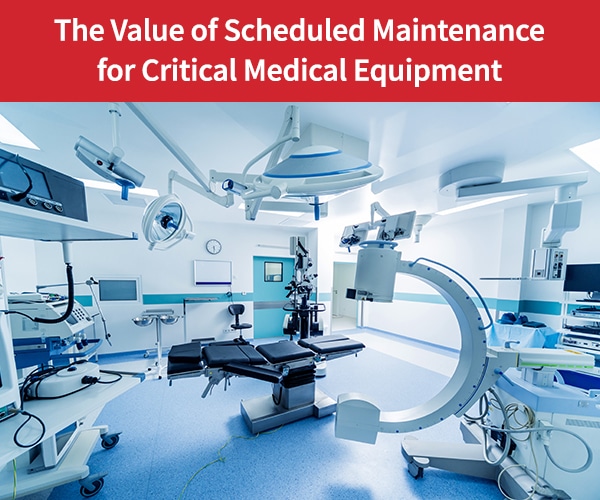

Ensuring the Continuous Operation of Life-Saving Equipment: Maintenance of Medical Equipment

Each country’s healthcare system is directly linked to its economy. It makes up a substantial part of society’s critical infrastructure and involves a large network of people and institutions coming together to improve the health of citizens through medicine and specialized equipment.

Technology and healthcare work hand-in-hand. Doctors and medical practitioners can’t possibly do their jobs without the help of medical devices, used to diagnose health problems as well as provide support for and monitor issues over time.

It is increasingly important to maintain equipment efficiency to provide the best level of care to patients dependent on it. For example, many of these specialized devices are used in life-threatening situations. Defibrillators are required to restore a normal heartbeat in a patient experiencing sudden cardiac arrest. Anesthesia machines provide an accurate supply of general anesthesia to those undergoing a medical procedure. These types of equipment are indispensable and can’t afford to fail. It is a matter of life, and death.

The Severity of Regular Maintenance for Medical Devices Highlights the Importance of Medical Equipment Maintenance Software

In heavily regulated industries such as healthcare, for medical device maintenance you must routinely maintain them to ensure they’re fully operational and run smoothly and safely without fail. When you’re dealing with people’s lives, medical mistakes caused by faulty or unusable equipment must be avoided at all costs.

Health institutions need to be able to count on reliable service companies that offer regular maintenance of medical equipment parts to protect their expensive investments, limit emergency repair calls and save lives.

Preventive maintenance in hospital settings can be managed through scheduling recurring work orders. Field service management software like Praxedo makes it easy for dispatchers to generate work orders automatically with predefined frequencies and assign them to specific technicians in the field.

Embracing technology to manage preventive maintenance of medical equipment

Scheduled maintenance aims to minimize equipment failure in critical sectors like healthcare. Medical equipment inspection and monitoring at regular intervals help hospitals and clinics better predict the likelihood of future failures and ultimately bypass reactive maintenance. Simply put, reactive maintenance refers to the process of repairing equipment malfunctions after they have already occurred. When people’s lives are at stake, the last thing you want to do is wait for this kind of service call to react. On the contrary, having a more proactive approach to maintenance calls with the help of field service management software increases productivity and improves overall customer satisfaction and patient care.

Preventive maintenance in hospitals is reshaping the healthcare industry in a variety of ways, including:

1. IMPROVED RELIABILITY OF MEDICAL EQUIPMENT

Safe and reliable products in hospitals have become imperative. The only way to maintain high-quality equipment is to perform periodic inspections to be able to predict problems before they happen.

Hospitals need to be reassured that the machines being utilized by their medical professionals work well all the time. Planning, tracking, and optimizing maintenance through medical equipment maintenance software increases equipment effectiveness and limits surprise breakdowns. It also makes technicians aware of what needs to be repaired on which piece of medical equipment so that nothing goes unnoticed.

2. REDUCED UNPLANNED DOWNTIME

Avoiding equipment downtime is essential in the medical field. Patients who are hooked up to devices absolutely need them to be functioning properly as their lives depend on it.

When equipment is maintained regularly and parts are replaced before they break, emergency repairs become a thing of the past. Issues can be dealt with months before failures occur to prevent unforeseen downtime, thus a reduction in medical mistakes. Technicians need to replace device parts early. Even though the precise lifespan of the apparatus is unknown, the most efficient way to do this is through maintenance scheduling.

In the medical sector, having a proactive medical maintenance strategy in place guarantees little to no unplanned downtime and doctors and nurses can treat patients with the highest quality healthcare. In addition, spare parts need to be on hand for the technician to carry out the work properly. Field service management software simplifies all the information – on work orders and spare parts – through recurrent work order functionality. Technicians can access work order data from their mobile device and receive important updates in real-time

3. EXTENDED LIFESPAN OF EXPENSIVE MACHINES

Many of the machines used in medical facilities are valued at thousands of dollars. Delivering the most efficient care means investing in highly advanced mechanical devices that are certified and follow specific regulatory programs. It is in the medical institution’s best interest to protect their investments and maximize the lifespan of these expensive products.

Generating work orders that are auto-scheduled so that technicians’ can check for signs of wear and tear are mandatory in highly regulated industries. Without field service scheduling software to automate processes and schedule these tasks in advance, the medical industry risks dealing with malfunctions that could have otherwise been avoided. Prolonging the life of vital medical equipment not only benefits the patient but saves the institution money that can be spent elsewhere.

Integration of IoT in Medical Equipment Maintenance

IoT is emerging as crucial for efficient medical equipment management and maintenance. IoT allows devices and systems to be interconnected and constantly monitor, collect, and analyze data, which is crucial for the proper functioning of vital medical equipment. This interrelated system enables real-time monitoring of the equipment’s performance so that the maintenance crew can address problems before they become critical.

Benefits of IoT in Predictive Maintenance

Among the significant benefits of IoT in medical equipment maintenance is the possibility of implementing predictive maintenance approaches. While reactive maintenance, as the name suggests, means fixing problems as they arise, predictive maintenance uses IoT data to anticipate equipment breakdowns.

Sensors in medical devices can send data on their environment, such as temperature, humidity, and usage. Other tools then analyze this data to forecast when a piece of equipment will fail. Technicians can perform repairs before they are needed. This approach also helps minimize the time taken and increases the safety of the patients since all the equipment is checked to ensure that it is in proper working condition.

Implementation Challenges and Solutions

IoT can significantly help in hospital equipment maintenance, but such systems can take time to implement. Incorporating IoT into existing medical equipment is complex and depends on various factors, such as compatibility. Furthermore, data protection and security issues arise, since most connected medical devices involve sensitive patient data.

To overcome these problems, healthcare facilities can implement IoT in stages, beginning with the most critical devices and gradually expanding the system. It is also essential to guarantee that cybersecurity measures are strong and that the organization adheres to applicable regulations. By engaging with IoT solution providers and enhancing staff training, healthcare organizations can effectively address these challenges and reap IoT’s benefits for equipment maintenance.

Advancement of Medical Equipment Management for Efficiency and Productivity

The advancement of medical equipment maintenance management software has played a pivotal role in boosting efficiency and productivity in healthcare settings. These systems store and track information about each piece of medical equipment, including radiologic equipment and biomedical equipment. This data encompasses everything from detailed maintenance history to nuanced equipment performance metrics.

Medical devices and equipment in a healthcare setting need to remain in good working condition to ensure patient safety and the best possible patient care.

The Impact of Maintenance History and Equipment Performance

Maintenance history provides valuable insights into the condition of medical equipment, offering an understanding of its lifespan, frequency of repairs, and overall reliability. For example, a piece of radiologic equipment might consistently show problems after a certain amount of usage. The maintenance history would reflect this pattern, alerting biomedical teams to potential future issues.

Understanding equipment performance and medical device maintenance is equally critical. For instance, a medical device that is constantly underperforming may not necessarily break down, but its reduced efficacy could impact patient care significantly. An equipment management system that continually monitors and records performance data can help technicians identify subtle performance issues and rectify them before they become serious problems.

Biomedical Equipment and Improved Patient Care

In the realm of patient care, the role of biomedical equipment maintenance cannot be overstated. These machines are the workhorses in hospitals, clinics, and other medical facilities. They are often involved in critical diagnostics, monitoring, and treatment procedures, making their maintenance and proper functioning a matter of life and death.

With the advancement of medical equipment management technology, hospitals, and other healthcare providers can not only ensure the maintenance of biomedical equipment but also optimize for the best performance. This proactive approach to equipment management helps increase efficiency, productivity, and ultimately, the quality of patient care. In this way, it is possible to maintain equipment maintenance in hospitals, leading to better patient care and overall healthcare facility effectiveness.

Reshaping the healthcare system one inspection at a time

Although these machines live in relatively safe and clean environments, they are utilized often, operated by multiple people, and have different purposes which can lead to premature, unexpected breakdowns. Furthermore, mechanical ventilation systems for critically ill patients sometimes run continuously, and for weeks at a time.

During last year’s public health emergency for example, medical device shortages were a huge problem. The demand for ventilators has been extremely high. The number of patients needing breathing assistance erupted, producing a relentless strain on the health care system. Hospitals across North America have been scrambling for more ventilators to help pump more oxygen into the lungs of people infected with severe breathing symptoms caused by COVID-19.

The pandemic has proved how fragile the economy is, how quickly things can change and how prepared the healthcare industry must be to tackle unprecedented events. The abrupt need for these critical machines only intensifies the importance of hospital preventive maintenance scheduling. And, automating the process ensures all devices are safe and effective. When push comes to shove, a systematic approach to medical equipment inspection will not only maximize the machine’s life, but also the patients.

Medical institutions use a wide variety of equipment for the prevention of diseases, diagnosis, treatment, and to monitor patient health conditions. These institutions spend hefty sums on specialized equipment for the doctors and nurses who rely heavily on them to save lives. To protect their expensive investments, hospitals expect superior and timely maintenance of hospital equipment from their service providers all year round.

Especially in the Covid-era, quality of services offered to patients in hospitals is highly dependent on efficient technology. However, many private and public healthcare facilities are constrained by budget restrictions and have aging equipment. Defective medical devices not only affect the degree of care provided to patients, but also the level of operational efficiency and medical facility’s reputation. To ensure the equipment is running optimally, regular medical device preventive maintenance is imperative.

A wide variety of medical systems is that much more complex to maintain

The wide variety of medical devices and equipment used to treat patients means stricter standards and regulations to abide by. Maintenance services must stay within a number of important parameters including industry field service management best practices, availability requirements, performance measures and cost control, among others.

Radiology departments and laboratories, for example, are burdened by many regulations and on top of that, feeling the pinch from the high costs associated with MRIs and other critical scanners breaking down unexpectedly. The abrupt strain placed on intensive care units and the complexity of the equipment makes first-class maintenance services all the more important.

To meet these high expectations, service providers must equip their field technicians with the appropriate mobile tools to ensure every healthcare device is properly maintained and adequately performing.

Preventive maintenance reduces the elevated costs linked to reactive maintenance or emergency breakdowns

For most healthcare facilities, preventive maintenance contracts are a significant investment. However, a proactive maintenance strategy is intended to anticipate system failure or deterioration through pre-defined checks that are scheduled in advance, decreasing total costs over time. Contracts that are preventive with a lower price point, help to avoid unexpected equipment downtime, thus reducing repair costs in the event of an emergency. Thanks to predetermined weekly, monthly or annual contracts, medical equipment maintenance and repair professionals provide better service delivery and save their customers money.

Field service software helps medical equipment repair and maintenance companies schedule customer visits and generate systematic reminders.

Speed and efficiency for any service call

When an unforeseen breakdown or malfunction occurs, the service provider must respond as soon as possible. That means identifying which technician is most qualified to repair the damaged medical equipment in the quickest way. A field software solution that centralizes planning, scheduling and technicians’ individual skill sets enables the dispatcher to swiftly pinpoint the right technician for the task.

The highest level of service success requires digital transformation

Critical medical device maintenance can’t be performed without the right digital tools for data collection and storage. In order to deliver true value to your customers in healthcare, business processes need to be digitized and accessible to teams at the office and in the field. For example, when a technician’s skill set and certifications are defined within the software tool, planning managers can dispatch the right person to repair an essential piece of equipment.

Collective data should be accessible at all times

When dealing with sophisticated medical equipment, you want your field technicians well-informed prior to each visit. You want to provide them with access to the history of repair and maintenance performed on each system. You need them to have important documentation such as previous work orders at certain locations, and other specifications on hand at all times. With field service management (FSM) software, technicians can view all of this information on their tablet or smartphone.

Additionally, the data must be accessible in online and offline mode. For this to happen, the above information needs to be consolidated in one place with the necessary technical and financial records linked to each piece of equipment. With these capabilities configured, a technician about to perform medical device preventive maintenance can be quickly alerted about a potential malfunction, thus avoiding major downtime.

Paperless information is easier to retrieve

Digitized information also makes it possible to trace all work orders performed on the equipment while also ensuring that the regulatory requirements have been respected. From a legislative point of view, any transaction not recorded on paper and/or digitally has technically never taken place. This is why it is essential to have a log of all of the operations that have taken place throughout the life of a piece of equipment. The digitization of this data allows automatic extraction for quality control. And, an electronic signature feature enables field technicians to validate work orders directly on site.

Our similar articles.

-

- Field Service Management

- Mobile App

- cloud-based

Cloud vs on-premise: The better choice for service businesses

July 14, 2022 -

- Customer Satisfaction

- Maintenance

- Gestion d’interventions

- Optimization

- Productivité

The Keys to Beating the Competition in Field Service Management

November 22, 2018 -

- Field Service Management

- Customer Satisfaction

- Gestion d’interventions

- SAV

- After-sales service

How to Handle Customer Complaints: 4 tips to effectively manage customer complaints

August 26, 2020